Understanding Heavy-Duty Thread

industrial lockstitch machine. From lightweight silks to heavy denim, this machine can sew through multiple layers with ease. Its adjustable tension settings and stitch length options make it versatile enough to tackle a variety of projects, from delicate clothing to sturdy upholstery.

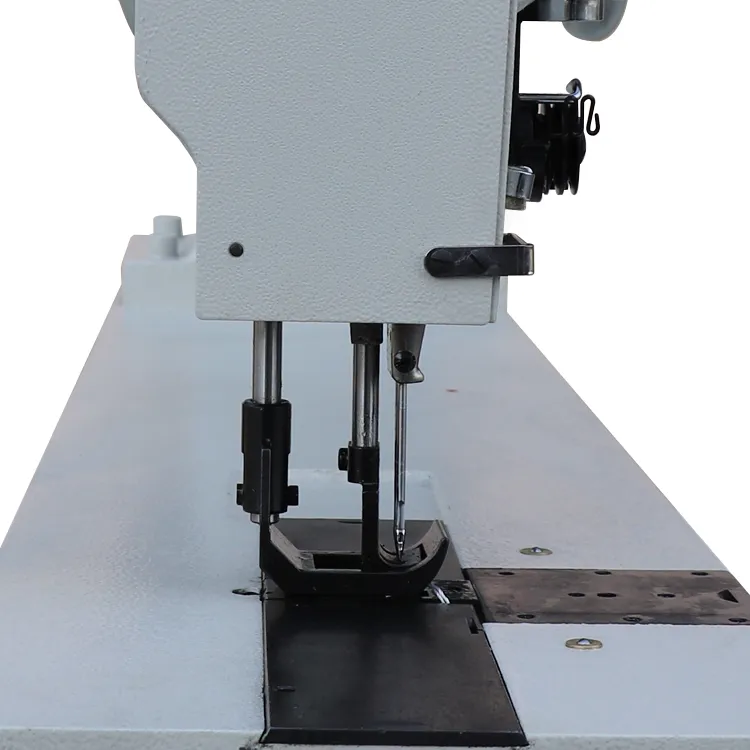

The design of the double needle sewing machine has evolved significantly since its inception. Originally developed to enhance sewing efficiency, modern double needle machines incorporate advanced technology, including electronic controls and computerized features. These enhancements facilitate precise stitching and reduce the likelihood of human error, thus improving overall productivity. The machine typically consists of two needles, two threads, and a single feed mechanism, which work in unison to create uniform and durable seams.